Wiha Top 3 Coated Special Bits For Industrial Applications

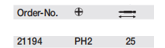

7011 D Diamond torsion bit, Phillips, style C 6.3.

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

under stress.

Coating: Extremely wear-resistant diamond-sapphire coating with a long service

life.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For fatigue-free work; ideal bit for frequent working.

Extra: Non-corrosive coating.

Diamond particles and sapphire particles

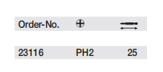

7010 DR DuraBit with torsion zone, phillip, style C 6.3.

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Torsion zone for protecting against premature breakage of bits under

load.

Coating: Hard-metal coating, extremely wear-resistant.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For effortless, safe working in demanding industrial applications and on

delicate surfaces.

Extra: Non-corroding nickel coating in combination with wolfram carbide

particles.

Extremely wear-resistant, hard-metal coated DuraBit tip gains a secure

hold in the screw head and guarantees a significantly greater service life

when compared to conventional diamond-coated bits.

Outstanding reduction of CamOut forces prevents slipping out of the bit

from the screw.

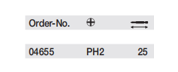

7010 TiN TiN Torsion bit, phillip, style C 6.3.

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Torsion zone for protecting against premature breakage of bits under

load.

Coating: Titanium nitride for extended tool life.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: Particularly suitable for screws that require frequent working